Fake ID Glossary of Terms

what the words we use to describe fake ID features mean in plain English

A strip of magnetic tape which is applied under the lamination of the card. This can be encoded on three tracks with cardholder data. When swiped in an appropriate card reader, the data in each track is read and displayed on screen.

More info about Magentic Stripes on Wikipedia

PVC stands for Poly Vinyl Chloride. It is a vinyl monomer which is converted into a polychloride resinous substance. Rolled into a thin substrate, it is die cut and laminated in to card shapes corresponding to the ISO 7810 card CR80 size. PVC is pliable, flexible, resistant to many corrosive elements. It retains printing very well.

Specifications of a standard plastic card like your ATM card.

Hologram Overlay / Holographic Overlay

A holographic overlay is a thin film with an embedded holographic image that is laminated or otherwise transferred to the surface of an ID card. The film is transparent and allows light to pass through, and refracts a security holographic image which is animated or otherwise detailed.

Examples of holographic overlays, youtube video.

This refers to when a cardholder signature is scanned and printed in black, against the background of a card image.

Scanned signature printed using an autopen.

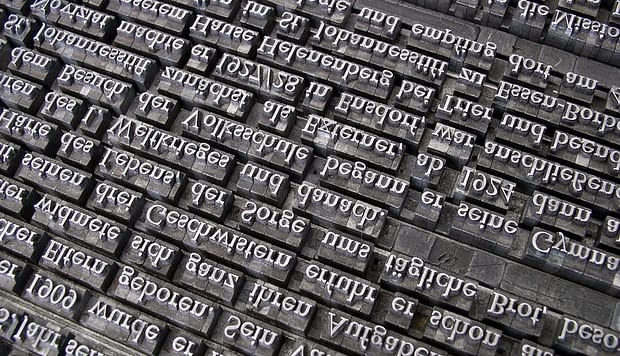

Microtext is an extremely small type size, which may not be visible to the naked eye. This can only be printed using a high definition printer.

Wikipedia article on microprinting.

Printed elements which inhibit the unauthorised reproduction of an Identity Document. Some features include microtext, colour rainbow gradients, void pantographs, intricate background designs, drape relief, ghost images, deliberate misspellings of microtext, grated images, Eurion images, magnetic ink, ultraviolet panels etc.

Information on anti-counterfeiting on US dollars.

An embedded integrated circuit chip which is drilled to the surface of a plastic card. Can be used to store cardholder data, secure applications and resident applications.

Thermal printing, or dye-sublimation printing, is the process by which solid ink in ribbon form is vaporised from solid to gas (without passing through the liquid stage, called sublimation), onto the surface of the card. This process is reasonably good but can result in faded and washed out images. Thermal printing is not terribly secure as it can be removed from the card with solvents.

High Definition Thermal Re-Transfer Printing

Retransfer printing uses the same dye-sublimation process to print the image, except the image is first printed onto a receptive transfer ribbon, which is then laminated using 175 C degree heat and pressure to the surface of the card. In effect, the image is irrevocably bonded to the card substrate.

This process is far more high definition than normal thermal printing.